- Details

Table of Contents

- Purpose

- General

- Responsibilities

- Guide Lines

- Flowchart (for the Netherlands only)

- References

- Attachments

1. Purpose

The purpose of this guide is to describe how the pump list, produced for submission to the Dutch Pressure Vessel Authority (currently named "Stoomwezen"), will be prepared and to provide information on its completion with relevant data.

2. General

The pump list is a document, which is based on the requirement set by the Dutch Pressure Vessel Authority to provide information on the type, the drive and the maximum differential pressure of pumps and compressors (ref. 6.1). It is a desirable document for grass roots process installations and a helpful document for existing installations.

The pump list has no formal status as a document and will, consequently, not be approved or stamped by the Dutch Pressure Vessel Authority. The submission of the information is a mandatory activity.

For non-Dutch projects, a pump list may be prepared if considered necessary or helpful for the assessment of design conditions (see also ref. 6.2 and 6.3); in such case, it is an internal Company document only and does not require submission to third parties.

3. Responsibilities

The Project Manager or his delegate has the overall responsibility for the preparation, checking and issue of the pump list.

The Project Engineering Group is responsible for the preparation of the pump list.

The Authority Engineering Group is responsible for the checking of the pump list and for providing advisory services during its preparation.

4. Guide Lines

4.1 Requirement for a Pump List

The Project Manager or his delegate should, in concert with the Authority Engineer, establish whether a pump list is necessary or desired for the project. He should also assign the individual engineer(s) responsible for the preparation of the pump list(s).

4.2 Form, Language and Document Numbering

4.2.1 Basic Form

The basic form is shown in Attachment 1 of this guide. The column numbers 1 through 11 in this Attachment have been added for easy reference and are not part of the form.

Blank pump list vellums are available with the Authority Engineering Group; see Attachment 2 for a copy. An 'electronic' version of the form can be developed per individual project if so desired.

4.2.2 Language

The language on the pump list should normally be Dutch for pump lists prepared for Dutch projects. The use of English is, however, generally accepted by the Dutch Pressure Vessel Authority.

4.2.3 Pump List Document Numbering

The pump list document lead number is defined in ref. 6.4 as '911' and should be used unless otherwise instructed by the Project Manager. A client document number should be added if required by the contract.

Note: For large projects, there may be more than one pump list; see Attachment 1.

4.3 Preparation

4.3.1 Supply of Data

The data for the columns 1 through 11 should be supplied by Process Engineering or taken from pump data requisition sheets and/or pump calculation sheets after these have been checked by Process Engineering.

The pump list can also be used for compressors and blowers.

4.3.2 Filling out the Pump List

The pump list should be filled out by the assigned project engineer(s) in cooperation with Process Engineering. Attachment 1 provides details for the various columns as necessary.

4.3.3 Completeness and Presentation of Data

The filled out pump list should be checked by the Authority Engineering Group for completeness and the way in which the data are presented. After this has been done, the list can be signed for 'checked'.

4.3.4 Approval and Issue

The pump list should be signed for approval and issue by the Project Manager or his delegate. After this step, the list is available for submission to the (Dutch) Pressure Vessel Authority. Client's comments are normally not collected, but the client is - also in the absence of contractual requirements regarding this point - entitled to receive a copy.

4.3.5 Actualization and Finalization of the Pump List

The pump list should be updated, at regular intervals, in accordance with information taken from (see also 4.4.2):

-

Measured performance curves of pumps and compressors, obtained from Procurement (Inspection or Vendor Document Handling Group).

-

Engineering flow scheme information on safety devices.

The Project Manager should decide whether "as built" finalization of the pump list is necessary.

4.3.6 Example of Completed Pump List

An example of a completed pump list is shown in Attachment 3.

4.4 Contacts with the Pressure Vessel Authority

4.4.1 Submission of the Pump List to the Pressure Vessel Authority

The pump list will be submitted to the Pressure Vessel Authority if desired or useful within the frame work of the assessment work done by that Authority. Such submission is, for Dutch projects, usually done by or via the Authority Engineering Group (see ref. 6.5).

4.4.2 Review by the Dutch Pressure Vessel Authority (Stoomwezen)

Stoomwezen will review during the assessment work the pump list and, during the preparation for the so-called "nader onderzoek" (see ref. 6.6), the test curve of each pump. Therefore, the pump list should reflect the actual situation and should be actualized from time to time (see ref. 4.3.5).

5. Flowchart (for the Netherlands only)

6. References

Document

Number Title Level

6.1 G-0401 Stoomwezen Rule "Behandelingsprocedures" -

6.2 BN-EG-UE1 Pressure Temperature Profile 5

6.3 BN-EG-UE2 General Rules to Establish Mechanical

Design Pressures and Temperatures 5

6.4 BN-W-UE301 Numbering of Project Documents 4

6.5 BN-EG-UE203 Submitting Information to Pressure Vessel

Authorities 5

6.6 BN-EG-UE206 "Nader Onderzoek" by Stoomwezen 5

7. Attachments

1. Notes regarding the preparation of the pump list (3 sheets).

2. Blank pump list form (1 sheet).

3. Example of completed pump list (1 sheet).

Notes Regarding the Preparation of the Pump List

1. Details For Filling Out The Various Columns

For the form and the numbering of the columns, see Attachment 2.

1.1 Columns 1, 3 and 11 (Pump Number, Density, Remarks)

The columns 1, 3 and 11 are self-explanatory. The molecular weight can be stated instead of the density for compressors and blowers.

1.2 Columns 2A and 2B (Capacity)

In the columns 2A and 2B the "normal" and "maximum" (rated) capacities as stated on the pump data requisition sheets should be indicated. The flows should be stated in kg/h for compressors and blowers.

1.3 Column 4 (Normal Suction Pressure)

Column 4 should state the suction pressure under normal operating conditions. Static head and tray pressure drop should be taken into account to avoid cumulative effects. For suction pressures below one (1) barg the use of the negative figure is preferred above the figure in bara.

Note: This is in accordance with Stoomwezen practices.

1.4 Column 5 (Maximum possible Suction Pressure)

Column 5 should indicate the suction pressure which occurs when the vessel from which is pumped is operating at the pressure for which it is protected or designed (i.e. opening pressure of relief valve or design pressure). Static head and tray pressure drop should be taken into account to avoid cumulative effects.

1.5 Column 6 (Normal Differential Pressure)

Column 6 should indicate the differential pressure at the (normal) operating point of the pump or compressor.

1.6 Column 7 (Maximum Differential Pressure)

Column 7 should indicate the maximum differential pressure. In the majority of cases, this will be at zero flow.

1.7 Columns 8 and 9 (Normal and Maximum Discharge Pressure)

Column 8 gives the sum of figures in columns 4 and 6, column 9 the sum of the figures in columns 5 and 7.

1.8 Column 10

Column 10 should indicate the setting of the discharge pressure safety device if installed. The setting shall normally be lower than the figure of column 9 and take static head effects into account.

Note: The preparation of the pump list may even lead to the conclusion, that such safety device is required.

The design pressure of the discharge piping - and sometimes equipment as well, depending upon how and where it is protected against overpressure - shall be equal to or higher than the figure of column 9, if no pressure safety device is or will be installed.

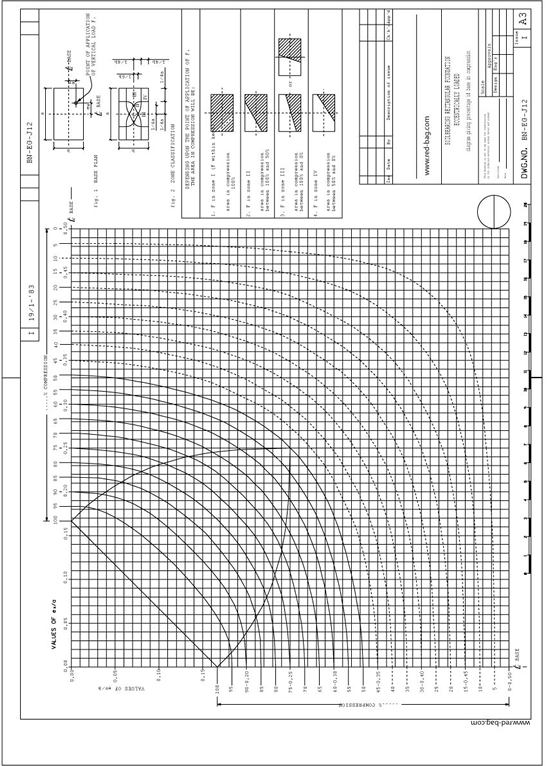

2. Shortcut Methods for First Issue

In some cases, the pump list will initially be prepared in an early stage of the project; pump and compressor curves, other that catalogue or proposal curves, are not available in that stage. For a reasonable estimate of the pressure levels, the following shortcuts can be used as a first approach:

2.1 For E-motor driven centrifugal pumps the maximum differential pressure should be taken as 120% of the normal differential pressure.

This figure should be checked against the actual figure once available (e.g. from the actually measured pump curve) and the necessary corrections should be made as necessary.

In some cases it is advisable to order pumps on basis of a specified maximum differential pressure; this does not replace the check against the measured pump curve!

Notes:

- Basically identical centrifugal pumps may still show different curves due to small differences between their impeller performance.

- Reciprocating pumps have almost always a pressure protection devise at their discharge side; the pump curve is, for these pumps, hardly a useful tool.

2.2 For turbine driven pumps the maximum differential pressure should be taken as 125% of the normal differential pressure; this figure should be checked against the actual figure once available (e.g. from the actually measured pump curve) and the necessary corrections should be made as necessary.

The design pressure of the equipment and piping in the discharge system should be carefully reviewed to establish the need for pressure protection devices.

3. Other Notes

3.1 Large projects usually involve more than one process unit; in these cases, it is advisable to prepare a pump list for each process unit. This will also simplify the communication with the Pressure Vessel Authority, if they require or use these pump lists.

3.2 Pumps with a dual service at different pressure levels should be treated with extra care. The discharge piping and equipment should be designed for the most severe possible combination of pressure and temperature up to and including the last block valve in the system. The pump list should, in such case, give the data for both services.

Note: Exceptions can sometimes be allowed for specific cases such as start-up lines and other infrequently occurring but carefully supervised operating situations. The decision to take such exception may be questioned by the Pressure Vessel Authority and should be well defendable.

3.3 Some chemical plants in particular can be sufficiently complicated to warrant a full investigation and qualification of all possible pumping circuits. Care should also be taken in situations, where two pumps may operate in parallel.

- Details

"Large parts of this procedure are not applicable anymore due to the recent European regulations such as PED"

Table of Contents

1. Purpose

The purpose of this guideline is to describe the way in which the "nader onderzoek" (final examination after installation) will be executed by Stoomwezen BV and which activities are required from the various Company Departments.

2. General

2.1 Terminology

The "Rules for Pressure Vessels" use the term 'pressure apparatuses' for equipment and systems under pressure, thus including vessels, reactors, heat exchangers, boilers, piping systems etc. The Rules are, in principle, made for Steam Act pressure apparatuses, but are also applied to Non-Steam Act pressure apparatuses (in the Netherlands generally known as "druktoestellen").

2.2 Justification of the "Nader Onderzoek" (Steam Act Pressure Vessels)

In accordance with the Steam Decree, section 12, subsection 5, (ref. 6.3) the examination of a steam or vapor apparatus also comprises a final examination, being an examination with regard to the set-up (or installation), lay-out and appurtenances of the apparatus.

The purpose of the examination is to satisfy Stoomwezen BV, that the plant or applicable part of it is safe and protected as intended by the Steam Decree. The detailed content of the examination is described in section 4 of this guideline.

2.3 Non-Steam Act Pressure Apparatuses

Non-Steam Act pressure apparatuses require only a "nader onderzoek" if the permit grant for the operating license of the subject facilities (based on the Environmental Management Act) contains a condition that such apparatuses have to be inspected by the "Dienst voor het Stoomwezen" or an organization accepted by the latter. For the purpose of this guide this accepted organization can be assumed to be Stoomwezen BV.

The formulation of this condition and its interpretation may vary from one permit grant to another.

2.4 Fulfillment of the Requirements of the Steam Decree

The Steam Decree (ref. 6.3) contains a large number of provisions regarding the appurtenances of steam and vapor vessels, which are elaborated, explained and supplemented in the "Rules for Pressure Vessels". With the exception of the provisions regarding:

-

safety valves, rupture disks and other appurtenances which serve to prevent that the allowable operating conditions will be exceeded, such as pressure, temperature and flow switches for cut out systems, and

-

appurtenances such as remotely operated level gauges on boilers,

these provisions are not verified by Stoomwezen BV on a preventive basis.

For documentation requirements see 4.2.4.

3. Responsibilities

The Authority Engineering Group, a member of which acts as Stoomwezen Coordinator (ref. 6.5 and 6.8), or the Representative/Deputy of the Stoomwezen Coordinator at site, has the prime responsibility for all coordination with Stoomwezen BV and guiding the activities to be performed by other Company Departments in relation to this guideline.

The Company Construction Department has the prime responsibility for the compilation of all field documents required and/or applicable for the "nader onderzoek" and for supporting the necessary activities in the field.

Other Company Departments involved in the "nader onderzoek" or aspects thereof may include, e.g., the Procurement Department (particularly the Inspection Group), the Engineering Department and the Process Department.

4. Guidelines

4.1 Timing, Request, Results and Duration

4.1.1 Timing of Execution

The "nader onderzoek" should be executed when the steam and vapor vessels have been erected (practically) "ready for operation", i.e. when the equipment items and the related other equipment inclusive of piping, control systems etc. are mechanically complete.

On larger projects, the "nader onderzoek" activities will normally be spread over a prolonged period, particularly for piping systems since these become ready over a longer period; combination with inspection work by a Stoomwezen inspector is recommended.

4.1.2 Request for "Nader Onderzoek"

The request for a "nader onderzoek" should be made in writing or by facsimile by the Stoomwezen Coordinator or by his representative/deputy at site. The request should be sent to the responsible Stoomwezen BV regional office for the attention of the agenda officer, at the latest about three (3) weeks in advance of the expected mechanical completion of the plant, unit or applicable part of it.

Before issuing the request it is advisable to check the following with the responsible Stoomwezen office :

-

how many equipment items are administratively ready for the ‘nader onderzoek’;

Note:

This information is usually available with the Coordinator as part of the document assessment activities.

-

which instrument testing is to be witnessed by Stoomwezen BV as part of the ‘nader onderzoek’ (for example : low level trips of boilers, temperature trips of furnaces, both simulated and actual)

-

Note:

-

In such cases, the instrumentation supervisor has to include such activities in his testing schedule in order to invite the Stoomwezen inspector.

Timing and extent of the "nader onderzoek" should be carefully coordinated with the Stoomwezen BV regional office because they need also some office time for preparatory activities. If done so, the examination will be effective and can take place as scheduled. See also 4.2.2.

4.1.3 Time Consumption of the "Nader Onderzoek"

Based on former experience, the "nader onderzoek" should be scheduled for approximately the following typical duration’s:

-

for a crude distillation unit 3 days

-

for a hydrotreater unit 1 day

-

for a distillate fractionation unit 2 days

-

for an amine unit 1½ days

-

for a utility distribution system 1½ days.

The duration for other types of units should be estimated in proportion with the above examples, noting that for practical reasons the duration should not be defined in periods shorter than ½ day.

If also a "nader onderzoek" for non-Steam Act pressure vessels ("drukvaten") is required, the duration can be estimated by multiplying the above figures with the ratio :

Steam vessels+vapor vessels+"drukvaten"steam vessels+vapor vessels

4.1.4 Result of the "Nader Onderzoek"

A successful completion of the "nader onderzoek" will result in the issue of a start-up permission to the client for the plant, the unit or part of it. Initially, such permission will have the format of a signed-off/stamped checklist or a simple written and signed/stamped document per item or system checked. The formal documents (CEOC-certificates, licenses and declarations of no objection) normally follow at a later date.

Pressure vessels and piping systems subject to licensing on basis of the Steam Act will receive a license. Pressure vessels subject to Stoomwezen inspection and acceptance on basis of the conditions of the environmental permit receive a declaration of no objection (“VGB”). All other pressure vessels inspected by Stoomwezen BV receive a declaration of manufacturing and first test (“VVB”).

4.2 Details of the Execution of the "Nader Onderzoek"

4.2.1 Systems Subject to a "Nader Onderzoek"

Systems subject to a "nader onderzoek" are all plants, parts of plants, plant systems and units, containing steam or vapor boilers and/or vessels, and/or piping systems subject to Stoomwezen approval.

For Non-Steam Act pressure vessels, which may include piping systems, the requirement for Stoomwezen approval exists only if the condition stated under 2.3 is fulfilled. The extent of the "nader onderzoek" then depends on the formulation of the condition of the permit grant.

No principle difference has been made between steam and vapor vessels and Non-Steam Act pressure vessels in 4.2.2 and further.

4.2.2 Appointment with Stoomwezen

The Company Construction Department, represented by the Coordinator's Representative/Deputy at site, should arrange for the appointment(s) with Stoomwezen BV to execute a "nader onderzoek".

For large(r) projects, the amount of work connected with the "nader onderzoek" -- including the office work which precedes the field activities -- is often sufficient to warrant formal scheduling by the Construction Department and prior discussion of the organization and the scheduling of the work with Stoomwezen BV (see 4.1.2).

4.2.3 Verification Activities by the Construction Department

Before the "nader onderzoek" can be started, the Coordinator's Representative/Deputy at site should verify or arrange for verification of the items listed below.

Nameplates and identification marks

Verify that the Stoomwezen nameplates and/or identification marks on all steam and vapor boilers and steam and vapor vessels are in accordance with the Stoomwezen rule on identification marks (ref. 6.6) and with the latest issue of the classification list(s) (ref. 6.2). If the "nader onderzoek" comprises also Non-Steam Act pressure vessels, then the same is applicable for all Stoomwezen nameplates on these vessels. Differences such as errors, missing data etc. should be reported to the Stoomwezen Coordinator to enable finalization of the classification list(s).

Verify that these Stoomwezen nameplates have been stamped on all four rivets or on all tack welds between equipment and nameplate with either the Stoomwezen symbol (lion) or with the corresponding symbol of the non-Dutch third party organization.

Notes:

-

Piping systems and very small vessels (volume equal to or less than 0.01 m3 normally do not have a nameplate; for these cases, the Stoomwezen symbol is stamped near the registration number, usually in front of or at the end of this number, or both.

-

Equipment that has been fabricated outside the Netherlands and that has been inspected by a local Third Party organization under the terms of EEC guideline 76/767/EEG (ref. 6.7), should have been stamped with the symbol of this Third Party Organization, who should be a member of the CEOC organization (see Attachment 3 of ref. 6.4).

Piping materials and systems

Verify that all piping materials and piping systems have been treated as described in the Guide for Coordination with Stoomwezen BV (ref. 6.8).

This implies in particular verifying that :

- marking and remarking of 'Stoomwezen' piping and fittings (with, e.g., heat number, factory mark, third party inspector stamp) have been carried out properly by the piping material manufacturers and the piping construction subcontractor;

- material certificates required by the "Rules for Pressure Vessels" and/or the Stoomwezen BV approval letters ("Nieuwbouwrapporten") for piping systems are available for the Stoomwezen BV inspector;

- all welding has been executed in accordance with the "Rules for Pressure Vessels" and/or the Stoomwezen BV approval letters for piping systems (properly qualified welders, welding procedures accepted by Stoomwezen BV, or, if fabricated outside the Netherlands, by an accepted local Third Party Organization etc.);

- test results such as radiographic films (with location plans), ultrasonic, magnetic particle and dye penetrant reports and hydrostatic test reports are available for the Stoomwezen BV inspector;

- reports on special treatments such as heat treatment are available for the Stoomwezen BV inspector;

- Stoomwezen BV register and -- if issued -- sequence numbers and the stamp of the Stoomwezen BV inspector who inspected the pipe spools before installation have been properly marked on the piping systems.

Notes:

-

Sometimes the register number will be placed on a weld-on plate.

-

Some piping shops have received a delegacy from Stoomwezen BV for pipe spool marking; in such cases, the stamp shall be placed by the assigned person of the piping shop.

-

For piping spools or systems fabricated outside the Netherlands, an inspector of a local Third Party Organization -- being member of the CEOC organization -- will often provide the stamping.

all information on the tag plates of safety valves matches with the safety valve certificates, referencing the safety valve item numbers on the classification list.

blow off lines of safety valves have open ends and that no obstructions (valves etc.) are located in these ends.

all relevant forms are legible, complete, signed and stamped by the manufacturer and/or piping construction subcontractor;

the latest issues of engineering documents such as engineering and utility flow diagrams, line designation tables and, for piping systems subject to formal stress assessment, the overall piping system drawing(s) is (are) available (see 4.2.4, B).

Notes:

-

It is recommended to prepare a centralized file of all documentation for this "nader onderzoek" and to ensure that the various documents can be easily related to each other by, e.g., using the heat numbers; this promotes the information retrieval and saves time during this last phase of the construction work. When agreed so with the Stoomwezen BV Inspector, he should be provided with storage facilities which are only accessible to himself.

-

To facilitate the checking of certificates by the Stoomwezen Inspector, a compilation should be made for each category of certificates, containing information such as size of the piping components involved, the heat number and the charge number. A number of columns should be included for use by the Inspector.

-

By acting in this way, the field inspection by Stoomwezen BV can, for piping systems, be limited to field welds, hydrostatic testing (if not yet done), register number checking, pipe supports checking on type, location and sometimes, operability and late changes to (parts of) the piping systems, if any.

-

For large(r) projects, a considerable portion of the 'paper work' should be (and is) done beforehand by Stoomwezen BV in order to reduce the field effort for the "nader onderzoek", i.e. during the piping (pre)fabrication and erection activities. The centralized file addressed under note 1 above will be a good tool for this work.

It is recommended that the verification activities will be performed, to the extent reasonably possible, at the receipt of equipment and materials, or otherwise during the installation activities.

4.2.4 Compilation of Documents

Before the "nader onderzoek" starts, the following documents should be compiled:

A. by the Authority Engineering Group (for submittal to Stoomwezen BV):

-

(copies or originals of) Test and Measuring Certificates ("meetbrieven") of safety valves and rupture discs in the plant, part of plant or system;

-

(copies of) test curves of pumps, compressors and blowers;

-

Note:To be submitted by manufacturer through the Company Inspection department.

-

further information and data as requested by Stoomwezen BV during the main procedure, for example information on alarm settings live tests, details on locking systems etc.

The desired documents and information should have been specified by Stoomwezen BV during the main procedure. The main procedure documents such as classification lists, line designation tables and engineering flow diagrams will have been submitted to Stoomwezen BV up to and including their latest issues as part of the main procedure (ref. 6.10).

Additionally, the following documents shall be submitted:

- the original CEOC-certificates as prepared by the local Third Party Organizations for equipment fabricated outside the Netherlands

- the manufacturing data books as prepared by the foreign manufacturers for equipment fabricated outside the Netherlands.

Notes:

-

These documents should, according to the Rules, be submitted by the manufacturers or the local Third Party organizations involved; since this does not always happen, follow up by the Inspection and/or the Authority Engineering group is necessary.

-

A verification by Company of both sets of documents to ensure that both show the same and the correct data is recommended to avoid delays and extra work due to non-acceptance by Stoomwezen BV.

B. by the Company Construction Department (to be available for the Stoomwezen Field Inspector:

-

(copies of) the Test and Measuring Certificates( “Meetbrieven”) of the relevant safety valves and rupture discs in the plant, part of plant or system;

-

(copies of) test curves of pumps, compressors and blowers;

-

all relevant engineering and utility flow diagrams;

-

copies of the classification list, the line designation tables (see 4.2.3, under “Piping Materials and Systems”) and any other documents as indicated by the Stoomwezen Coordinator.

4.2.5 Assistance to Stoomwezen BV

During the "nader onderzoek", the Coordinator's Representative/Deputy at site should be available or arrange for the availability of an engineer to assist Stoomwezen BV and/or to be present with the examinations.

4.2.6 Stoomwezen BV Activities

During the "nader onderzoek", Stoomwezen BV will execute the following activities.

A. Office activities:

-

check of all engineering and utility flow diagrams for the safety protection of equipment;

-

check of all test curves of pumps, compressors and blowers as specified by themselves;

-

check of test and measuring certificates of safety valves and rupture discs, as specified by themselves;

Note:

Safety valve certificates comply with Stoomwezen requirements if they contain information on (1) the height of the government ring (2) the spring diameter, the spring wire thickness, the unloaded spring length and the number of windings.

-

verification of the further information and data as requested by themselves during the main procedure (see 4.2.4);

-

verification of the original CEOC-certificates received from the Authority Engineering Group, from the manufacturers or from the local Third Party Organizations for equipment fabricated outside the Netherlands, against the manufacturing data books and the classification lists; these documents will be kept by Stoomwezen BV for the preparation of licenses and declarations of no objection

-

verification of the manufacturing data books received from the Authority Engineering Group, from the manufacturers or from the local Third Party Organizations, for compliance with the inspection requirements contained in the approval letters of the equipment fabricated outside the Netherlands; these documents will be returned by Stoomwezen BV after review and acceptance.

This document checking will, whenever possible, be done in the Stoomwezen BV office in order to minimize their field activities, particularly on smaller projects where no Stoomwezen BV inspector will be permanently assigned to the project.

The results of the checking and verification activities is laid down in a so-called 'Nader onderzoek rapport' for the individual equipment items and piping systems subject to a license, a declaration of no-objection or inspected and tested on specific Company/Client request.

Note:

Equipment items and systems NOT subject to a license or a declaration of non-objection are normally not checked by Stoomwezen BV.

B. Activities for equipment constructed at site:

For equipment items that are constructed or erected at site, either entirely or from pre-assembled parts, some Stoomwezen related activities are required at site; typical examples include large storage vessels including spheres and large furnaces, boilers and heaters.

Such activities include (without necessarily being complete):

-

contacts with Stoomwezen BV for fabrication inspection, final inspection and acceptance at site

-

definition of hold points with and for Stoomwezen BV inspection (e.g., fit ups)

-

document review by Stoomwezen BV

-

definition of hold points with and for Stoomwezen BV inspection (e.g., fit ups)

-

document review by Stoomwezen BV

-

hydrotest in the presence of Stoomwezen BV

-

the "nader onderzoek" by Stoomwezen BV when all piping has been connected and all appurtenances have been installed

-

stamping of nameplate by Stoomwezen BV at successful completion of the "nader onderzoek".

These activities are normally included with the subcontract for construction/erection.

The Coordinator's Representative/Deputy has only a supervisory role for these activities.

C. Field activities:

-

visual field check of the plant or units as installed against the engineering and utility flow diagrams;

-

field check of all steam and vapor boilers and vessels for registration number and Stoomwezen BV or CEOC member symbol on the nameplates; in case also "drukvaten" have to be inspected the same applies to these vessels;

-

presence with hydrotests of piping systems if done at site;

-

field check of safety valves, including interlock systems etc., as installed;

-

presence during the blow-off of boiler safety valves;

-

check on the proper functioning of automatic starting devices for spare pumps, the cut-out systems for, e.g., furnaces and reboilers and/or other essential safety systems;

-

any further check on safety systems as required by themselves; such further checks will normally have been specified during the main procedure for the project (see ref. 6.9/6.10).

4.2.7 Follow-up on Stoomwezen BV Activities

Any notes or remarks made and/or any corrective actions specified by Stoomwezen BV during the "nader onderzoek" should be resolved or executed on a mutually agreed basis. This includes corrections of administrative nature such as removal of errors in CEOC-documents.

Stoomwezen BV may, at their option, issue a conditional start-up permission or hold this permission until the outstanding points have been cleared.

Note:

The so-called 'hold points' are often related to essential safety items; the emphasis is laid on equipment items and systems subject to a license or a declaration of non-objection, since non-compliance’s with these items or systems may have juridical consequences for Stoomwezen BV.

5. Preparation of the Guide for Projects

Because each project is different again the above guidelines should be reviewed when they will be used for a project. For smaller projects some simplifications may be possible, for other projects additional agreements with Stoomwezen BV may be useful.

If it is decided to modify the guidelines for a specific project, a separate document should be issued for this project.

In turn, specific experiences from a project may lead to an update or modification of these guidelines.

6. References

|

Document Number

|

Title

|

Level

|

|

| 6.1 | BN-EG-UE203 | Defining Information to be Submitted to Pressure Vessel Authorities | 5 |

| 6.2 | BN-EG-UE214 | Preparation of Equipment Classification Lists for the Dutch Pressure Vessel Authorities | 5 |

| 6.3 | G-0203 | Steam Decree (1953, with updates) as contained in the "Rules for Pressure Vessels" | - |

| 6.4 | G-0301 | Stoomwezen Rule, "General Procedure" | - |

| 6.5 | G-0401 | Stoomwezen Rule, "Procedures for Pressure Vessels in Installations" | - |

| 6.6 | G-0601 | Stoomwezen Rule, "Identification Marks" | - |

| 6.7 | 76/767/EEC | Guideline Regarding the Acceptance of Inspections Executed by Local Inspection Organizations | - |

| 6.8 | BN-EG-UE... (later) | Guide for Coordination with Stoomwezen BV | 5 |

| 6.9 | BN-EG-UE217 (later) | Guide Regarding Procedural Information Stoomwezen BV | 5 |

| 6.10 | BN-EG-UE218 (later) | Guide for Information to be Submitted to Stoomwezen BV | 5 |

Note:

References 6.9/6.10 are available as Attachments 1 and 2 of Ref. 6.1, Defining Information to be Submitted to Pressure Vessel Authorities (BN-EG-UE203).

- Details

This is a LIVE STUDY document and will be changed without notice. The content may contain errors and omissions.

|

ASME B31.1 (2008) |

ASME B31.3 (2008) |

ASME B31.8 (2007) |

|---|---|---|

|

Power piping: typically found in electric power generating stations, in heating and cooling systems |

Process piping: typically found in petroleum refineries, chemical, pharmaceutical, textile and paper plants |

Gas transportation and distribution systems: piping transporting products, predominantly gas |

|

Applicable: boiler external piping from first joint up to and including first block valve for boilers where:

Excluding: fatigue due to pressure cycling

|

Exclusions:

Including: fatigue due pressure cycling and thermal cycling

|

Exclusions:

|

|

Allowable stress:

|

Allowable stress:

|

Allowable stress:

|

|

Materials: material of unknown specification shall not be used for pressure containing components |

Materials: material of unknown specification shall not be used for pressure containing components |

Materials: material only as per Appendix A |

|

Quality factor E: depending type of weld, radiography and material |

Quality factor E: depending type of weld, radiography and material |

Quality factor E: depending type of weld, radiography and material |

|

Factor y: factor depending Ferritic, Austenitic, Nickel and design temperature |

||

|

Factor W: weld strength reduction factor |

Factor W: weld strength reduction factor |

|

|

Factor f: stress range factor |

||

|

Factor F: design factor |

||

|

Factor T: temperature derating factor, compensate material allowable stress values for temperature, Table 841.166A |

||

|

Pipe under internal pressure (104.1.2 and 104.1.4 (in creep)):

P = internal design pressure D0 = outside diameter of pipe SE = maximum allowable stress, including quality factor tm = minimum required thickness y = coefficient table 104.1.2A A = additional thickness to compensate threading, provide additional strength, corrosion allowance W = Weld strength reduction factor when in creep range, is 1 outside creep range (table 102.4.7) |

Pipe under internal pressure (304.1.2):

P = internal design pressure D = outside diameter of pipe S = stress value for material E = quality factor t = pressure design thickness y = coefficient, also from table 304.1.1 W = Weld strength reduction factor |

Pipe under internal pressure (841.11):

P = internal design pressure D = nominal outside diameter of pipe S = specified minimum yield strength E = longitudinal joint factor, table 841.115A t = wall thickness F = design factor from table 841.114A T = Temperature derating factor from table 841.116A |

|

Bend under internal pressure (102.4.5):

pipe under internal pressure where I for intrados is:

and I for the extrados is:

and at sidewall I = 1.0, R = radius of pipe bend

|

Bend under internal pressure (304.2.1):

pipe under internal pressure where I for intrados is:

and I for the extrados is:

and at sidewall I = 1.0, R = radius of pipe bend

|

Bend under internal pressure (841.231): For cold bends the deflection of longitudinal axis and the radius is limited according table in paragraph 841.231

Hot bends are to be designed and manufactured according ASME B16.49, the internal pressure rating shall not be less than that which is calculated for straight seamless pipe and the intrados wall thickness should be:

where the t the wall thickness of the pipe is

|

|

Elbows under internal pressure (102.4.5): Elbows manufactured according standards listed in Table 126.1 are suitable for use at the pressure-temperature ratings specified by such standards.

Elbows not according above standards or for which design formulas and not given in the code shall be based on calculations consistent with the design criteria of this code. These calculations shall be substantiated by one or more of the means stated in A B C or D of 104.7.2 (Does this mean or allow that an elbow can be calculated according a bend with uniform thickness? Refer B31.3) |

Elbows under internal pressure (304.2.1): Elbows manufactured according standards listed in Table 326.1 are suitable for use at the pressure-temperature ratings specified by such standards.

Elbows not according above standards or for which design formulas and not given in the code shall be based on calculations consistent with the design criteria of this code. These calculations shall be substantiated by one or more of the means stated in A B C or D of 304.7.2, or the elbow can be calculated according the Bend calculation, refer 304.2.2. |

Elbows under internal pressure (841.231?): No specific design rules are listed for fabricated elbows

(Does this mean or allow that an elbow can be calculated according a bend with uniform thickness? Refer B31.3) |

|

Miter bends under internal pressure (104.3.3): 1. Only straight pipe calculations required if:

2. Pressure shall be limited to 70 kPa if:

and thickness is not less than required for straight pipe 3. Pressure shall be limited to 700 kPa if:

and thickness is not less than required for straight pipe 4. For pressure over 700 kPa: proof test, FEA, etc required with a defined minimum for closely spaced and widely spaced miter bend

|

Miter bends under internal pressure (304.2.3): 1. When theta =< 22.5 deg than max. allowable pressure shall be the lesser of (t = T - c):

and

2. When theta > 22.5 deg than max. allowable pressure shall calculated as (t = T - c):

For all miter bends the R1 shall not be less than:

with A: (T-c) =< 13 mm → A = 25 13 < (T-c) =< 22 mm → A = 2(T-c) (T-c) > 22 mm → A = 2(T-c)/3 + 30 |

Miter bends under internal pressure (841.232): 1. If system hoop stress > 40% of specified minimum yield strength miter bends are not permitted. Deflections caused by misalignment up to 3 deg are not considered as miters. 2. If 10% < hoop stress < 40% SMYS the deflection of each miter shall not exceed 12.5 deg. 3. If hoop stress < 10% SMYS the total deflection angle shall not exceed 90 deg. 4. If hoop stress > 10% SMYS the distance measured at the crotch shall not be less than one pipe diameter

|

|

Reducer under internal pressure (104.6): 1. Flanged reducer according Table 126.1 are considered suitable at the specified pressure temperature ratings. 2. Where butt welding reducers are made to a nominal pipe thickness, the reducers shall be considered suitable for use with pipe of the same nominal thickness. 3. Components not covered by the standards listed in Table 126.1 shall be based on calculation consistent with this code. Calculations are to be substantiated by one of: - extensive, successful service experience - experimental analysis - proof test - detailed stress analysis, such as finite element analysis (Is ASME VIII div.1 UG32 acceptable?) |

Reducer under internal pressure (304.6.1(b)): 1. Reducers according Table 326.1 shall be considered suitable for use at established pressure-temperature ratings or corresponding straight pipe with 87.5% of nominal wall thickness. 2. Concentric reducers not listed in Table 326.1 may be designed according closures as per ASME VIII div.1 3. Eccentric reducers not listed in Table 326.1 are qualified as unlisted components and shall be designed and documented substantiated by one of: - extensive, successful service experience - experimental analysis - proof test - detailed stress analysis, such as finite element analysis (Is ASME VIII div.1 UG32 acceptable?) |

Reducer under internal pressure (831.373): 1. Steel butt welded fittings shall comply with ASME B16.9 or MSS Standard Practice and shall have pressure and temperature ratings based on stresses for pipe of the same of equivalent material (831.31b) 2. Other pressure containing components shall be designed the according design philosophy of this code substantiated by one of: - extensive, successful service experience - experimental analysis - proof test - engineering calculations 3. Closure heads such as flat, ellipsoidal, spherical or conical heads are allowed for use under this code. Such items may be designed in accordance with ASME VIII div.1 (UG32). |

|

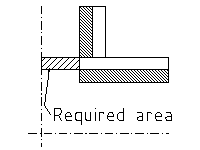

Stubon under internal pressure (104.3.1(D)): Required reinforcement area is

with

tr is reinforcement pad thickness

Assessment: Area A2,A3, A4 and A5 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 104.3.1(D.2.3))

|

Stubon under internal pressure (304.3.3): Required reinforcement area is

Assessment: Area A2, A3 and A4 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 304.3.3(f3))

If |

Stubon under internal pressure (831.4 and app. F): Required reinforcement area is (Fig. F-5):

Assessment: Area A2 and A3 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 831.4(f))

|

|

Tee (extruded outlet) under internal pressure (104.3.1(G)): Required reinforcement area is

K = 1.0 when K = K = 0.7 when

Assessment: |

Tee (extruded outlet) under internal pressure (304.3.4): Required reinforcement area is

K = 1.0 when K = K = 0.7 when

Assessment: If If |

Tee (extruded outlet) under internal pressure (831.4 ref. App. F): Required reinforcement area is

K = 1.0 when d/D > 0.60 K = 0.6+(2d)/(3D) when 0.15 < d/D <= 0.60 K = 0.7 when d/D <= 0.15

Assessment:

|

|

Weldolet (branch) under internal pressure (104.3.1(D)): Required reinforcement area is

with

Assessment: Area A2,A3, A4 and A5 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 104.3.1(D.2.3)) |

Weldolet (branch) under internal pressure (304.3.3): Required reinforcement area is

with

Assessment: Area A2, A3 and A4 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 304.3.3(f3)) |

Weldolet (branch) under internal pressure (831.4 ref. App. F): Required reinforcement area is (Fig. F-5):

Assessment: Area A2 and A3 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 831.4(f)) |

|

Cap under internal pressure (104.4.1(B)):

Can be calculated with ASME VIII div.1 UG-32 app.1-4

L = radius dish r = radius knuckle

|

Cap under internal pressure (304.4.1(b)): Can be calculated with ASME VIII div.1 UG-32 app.1-4

L = radius dish r = radius knuckle

|

Cap under internal pressure (831.372 and 831.373): Can be calculated with ASME VIII div.1 UG-32 app.1-4

L = radius dish r = radius knuckle

|

|

Flat closure under internal pressure (104.4.1(b)): Can be calculated with ASME VIII div.1 UG 34 …

|

Flat closure under internal pressure (304.4.1(b)): Can be calculated with ASME VIII div.1 UG 34 …

|

Flat closure under internal pressure (831.373): Can be calculated with ASME VIII div.1 UG 34 … |

|

Flange under internal pressure (104.5.1(B)): Can be calculated according ASME VIII div.1 app. 2 using B31.3 allowable stresses and temperature limits with:

|

Flange under internal pressure (304.5.1(b)): Can be calculated according ASME VIII div.1 app. 2 using B31.3 allowable stresses and temperature limits with:

|

Flange under internal pressure (831.2): Allowed to use: ASME B16 series as listed in Appendix A such as B16.5. Also MSS SP-44. For slip-on welding flanges reference is made to ASME VIII div.1 design.

Can ASME VIII div.1 be used for calculation? |

|

Blind flange under internal pressure (104.5.2(B)): Can be calculated according ASME VIII div.1 UG-34 with:

|

Blind flange under internal pressure (304.5.2(b)): Can be calculated according ASME VIII div.1 UG-34 with:

|

Blind flange under internal pressure:

Can ASME VIII div.1 be used? |

|

Blanks (spade) under internal pressure (304.5.3(B)):

|

Blanks (spade) under internal pressure (304.5.3(b)):

|

Blanks (spade) under internal pressure:

Can ASME VIII div.1 be used? |

- Details

Company

Engineering procedure for the preparation of process flow diagrams P-T profiles engineering flow diagrams utility flow diagrams interconnecting flow diagrams process safeguarding flow diagrams revamping flow diagrams and line tables

Table of content

-

Introduction

1.1 Purpose

1.2 Concept

1.3 Use

1.4 Types of Diagrams

1.5 Notes -

Scope

-

General procedure for flow diagram preparation

3.1 Layout and Format

3.2 Symbols and Identification

3.3 Diagram Issues -

The process flow diagram

4.1 General

4.2 Initial Process flow diagram

4.3 Kickoff Meeting

4.4 Process flow diagram drafting

4.5 Reissues of process flow diagrams

4.6 Computer vision diagram systems -

The Pressure (p) – Temperature (T) profile

5.1 General5.2 Purpose

5.3 Reissues of P-T Profile

5.4 Computer Vision Diagram Systems -

The Engineering flow diagrams

6.1 General

6.2 Initial Engineering flow diagram

6.3 Pipelines and pipelines referencing

6.4 Initial flow diagram check

6.5 Diagram review meeting

6.6 Engineering flow diagram drafting6.7 Reissues of Engineering flow diagrams

6.8 Computer vision diagram systems -

The utility flow diagrams

7.1 Purpose

7.2 Preparation

7.3 Layout

7.4 Control systems, valves, etc.7.5 Equipment

7.6 Example diagram

7.7 Example diagram -

The interconnecting flow diagrams

8.1 Purpose8.2 Split of work

8.3 Layout

8.4 Example diagram -

The process safeguarding flow diagrams

9.1 Introduction

9.2 General consideration

9.3 Purpose

9.4 Timing and preparation of process safeguarding flow diagram

9.5 Presentation -

The revamping flow diagram

10.1 General

10.2 Updating and Marking engineering flow diagrams10.3 Example diagram

-

Check list

-

preparation of line tables

12.1 Responsibility

12.2 Format

12.3 Description of Columns

12.4 Procedure

12.5 Computer vision systems

12.6 Sample forms -

List of related Company standards

-

List of standards other than Company

14.1 General

14.2 U.S.A.

14.3 West Germany

14.4 Great Britain

14.5 France

14.6 The Netherlands

14.7 S.I.P.M.14.8 Aramco

-

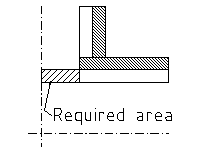

Typical arrangements of equipment installation

15.1 General

15.2 Vessels and columns

15.3 Shell & Tube heat exchangers

15.4 Aircoolers

15.5 Pumps

15.6 Turbines

15.7 Ejectors

15.8 API

15.9 Control stations15.10 Utility tie-ins into process lines

15.11 Battery limits installations

15.12 Sample stations

15.13 Safety relief valves

15.14 Burner installations15.15 Steam trap assemblies

15.16 Instrument purges

15.17 External seal flush and purge

15.18 Cooling rotating equipment15.19 Flushing oil

15.20 Blowdown systems

15.21 Level instruments and stand pipes

15.22 Instrumentation compressors

15.23 Valve type selection

15.24 General instrument requirements15.25 Utility header valve requirements

1. Introduction

1.1 Purpose

The purpose of this document is to outline the procedures for the preparation of process flow diagrams, pressure-temperature profile diagrams, engineering, utility and interconnecting flow diagrams and special diagrams as revamp flow diagrams and pressure safeguarding flow diagrams.

1.2 Concept

Flow diagrams are highly specialized “language” for information transfer. They represent the engineer's concept of how plant equipment should be interconnected. The diagram is almost physical in a sense, since every piece of equipment, every pipeline, valve and instrument is shown. Diagrams are used to convey information between groups working on the project and translate the plant design into “real” piping and equipment.

1.3 Use

By preparing the diagrams properly, the engineer can convey a great deal of technical information, quickly and accurately, with a limited amount of paper work.

1.4 Types of diagrams

There are 7 types of flow diagrams:

1.4.1 The process flow diagram (PFD)

The PFD is developed by the process engineering department. Final drafting by the flow diagram squad.

On this document are given the main process equipment., fluid flows, main control loops and critical valves. It is a tool for the process engineer(s) to convey information to project and specialist engineers to design the installation in detail (see fig: 6)

1.4.2 The Pressure Temperature Profile Diagram (PTP)

The PTP diagram is a document prepared by the Process Engineering Department with the purpose of providing project, control systems and piping engineers with the correct pressure and temperature correlations between the various piping systems, vessels, exchangers, etc.

The document ensures that proper values are being used for preparation of data sheets, line tables and other documents as, e.g. painting systems, insulation, etc.

For PTP preparation procedures refer to Standard Specification BN-EG-UE-1 (Design guide for Pressure and Temperature profile).

1.4.3 The Engineering Flow Diagram (EFD)

On this document are shown all equipment connecting piping, utility piping, complete with control loops and all other instrumentation, all valves and safety measures. It is the main tool for the project engineer to convey information to the piping design office and control systems engineering group for the detailed piping and control systems design (see fig:13)

1.4.4 The Utilities Flow Diagram (UFD)

This document shows how utilities are generated and distributed from the source or supply point to the various parts of an installation. The diagram shows common control loops, additional equipment that is deemed necessary to supply the utility as required and the safety measures necessary (see fig: 18). The diagram shall be drawn in accordance with the geographical layout of the plant.

The diagrams are generally divided per generation activity, e.g. steam generation, instrument air, cooling water, fuel oil, etc. The utility equipment shall be shown. Packaged units to be shown within heavy dotted line.

1.4.5 The Interconnecting Flow Diagram (IFD)

These diagram are prepared to show the interconnecting lines between various plant units and, e.g. tank farms, etc.

1.4.6 The Process Safeguarding Flow Diagram (PSFD)

This document shows the correlation of safety devices installed but indicated on separate EFD's. It “highlights” the final level of protection provided by the safety systems installed.

This document will be produced on client's request only, e.g. SIPM.

1.4.7 Revamp Flow Diagram (RFD)

“Revamping Flow Diagram” shall be prepared to indicate which equipment, lines, control loops, etc. must be demolished, modified, removed or relocated, etc. in a revamping project. The existing engineering flow diagrams of a plant or unit to be revamped shall be used.

In general two sets of diagrams are to be prepared:

a. An updated existing EFD's version for demolishing purposes RFD's.

b. New “as built” EFD's

For more details refer to chapter 10

1.5 Notes:

1.5.1 It must be noted that particular instructions given by client or licensor with respect to his requirements or special requirements covered by any authority decrees shall be observed.

1.5.2 If any of such rules, decrees or instructions exist, these must be mentioned in the “Project Specification”.

1.5.3 When these instructions have not been incorporated, the documents produced will be unacceptable to the client or licensor and/or authorities.

1.5.4 Where in the following text of this Engineering Procedures has been referred to other Company procedures or standards, this is only true where the Company standards are not conflicting with those mentioned under par 1.5.1.

1.5.5 To obtain maximum uniformity with regard to line thickness, lettering, symbols, etc. the drafting on vellums shall be executed by the Flow Diagram Squad.

1.5.6 There is still another flow diagram, prepared by the control systems engineering group, exclusively for use by process and control systems engineers. This flow diagram is principally a PFD on which the control system engineer indicates specific instrument physical data: the document is called: “Instrument Data Flow Sheet”. It is not further mentioned in this “Engineering Procedures”.

1.5.7 The examples presented in this Engineering Procedure are taken from actual jobs and include general Client's requirement. Therefore, the symbols used will not always be identical to the symbols shown on the legend sheet fig:22

1.5.8 On an EFD, a package unit, e.g. compressor, can be indicated with a heavy drawn block with reference to one or more vendor flow diagram (process, lube oil, seal oil, water cooling, etc.) which can be adopted.

2. Scope

2.1 This Engineering Procedure shall be used as a standard for the preparation of precess and engineering flow diagrams as outlined in para 1.4 of the introduction.

2.2 It shall also be used to edit systematically the text for the project specification on the subject of flow diagram preparation.

2.3 The purpose of this Engineering Procedure is to provide the engineers with all necessary information to generate the various diagrams needed with the greatest consistency and efficiency possible.

3. General Procedure for flow Diagram Preparation

3.1 Layout and Format

3.1.1 Vellums

All formal diagrams shall be drawn on standard A-1 size vellums (vellum size 594x841mm, including 10mm edge). In those cases where the project specifications ask for drafting on client's standard forms, the size may be different from the A-1 size.

3.1.2 Title block

The PFD, EFD and other diagrams shall bear in the right hand bottom corner of the diagram the standard Company title block. In cases where project specifications ask for specific use of client's vellums with client's title block, a standard Company drawing number sticker shall be added to the drawing for use of Company drawing record (see figure 1a).

Fig. 1a

In cases where client forbids the use of Company drawing number sticker, the Company drawing number shall be outside the drawing boundary line (see fig:1b).

The title block shall be completed with information as unit number unit name, unit section, drawing number, and all other information that is necessary to give all drawing-related information.

3.2 Symbols and Identification

3.2.1 For each project the engineering and utility flow diagrams will use the Company standards, if not overruled by client's licensor's or authority's requirements. These technical documents are:

BN-DS-C1 General information and Explanation of the Company symbols

BN-ES-C1 Standard symbols for Process and Engineering Flow Diagrams

BN-ES-K1 Standard for Identification of Instruments.

3.2.2 All symbols, instrument identifications and abbreviations used must be conform to those shown in above given standards, unless otherwise noted in the project specification.

In other cases a new legend sheet is to be prepared, which includes the required symbols and abbreviations. Project shall decide, in consultation with client or licensor, which system has to be used.

3.2.3 All equipment shown on the process and engineering flow diagram shall be identified with both name and number as listed on the equipment list.

Placement of titles shall be as follows:

a) Towers, tanks, tubulars, general equipment and other items on or above the upper base line shall be identified with titles placed across the top of the diagram. In some cases a space shall be provided to indicate design and/or operating conditions.

b) Pumps, compressors, etc. on the lower base line. Space shall also be provided to give design/operating conditions, if required.

3.2.4 To save drafting time, the flow diagram squad may make use of preprinted self-adhesive stickers to be stuck to the front or the back of the flow diagrams. These stickers can be adapted to any project an requirement.

3.2.5 Sticker samples

3.3 Diagram Issues

3.3.1 Issue numbering

It is of utmost importance that flow diagrams are kept up to date continuously and are regularly to keep all disciplines informed of the change during the engineering stage.

A release for design issue of flow diagrams shall be made directly after incorporation of Client's comments. Any further change after this issue mad by the Client shall be a subject for a change order.

The reissues shall be distributed in accordance with the job document distribution schedule.

All issues shall be numbered, dated and provided with a short description of the reason for reissue in accordance with QA procedure 006.

Typical example

The issue number shall be in accordance with the required numbering system as given in the job project procedure.

3.3.2 Revision list

All issues distributed after the “preliminary piping materials B.T.O.” shall be accompanied by a “revision list” on standard form BN-UD-101 “List of Revisions”.

This list of revisions (change) shall be issued as an addendum to the revised flow dagram. Each new diagram issue shall be accompanied by such a list of revisions.

3.3.3 Internal Issues

In some cases it may be required to distribute a diagram exclusively for the use within the BBV organization only.

It shall be clear that the number of such “Internal Issues” shall be kept to an absolute minimum. It is even better to have none at all.

In the case however, that an internal issue is necessary, the numbering procedure is as follows:

A circle of 16 mm diameter shall be drawn at the left hand side of the diagram title block and on the backside of the vellum. The circle shall be divided in two parts by a horizontal line.

An index capital A, B,etc. shall be pencilled in the top half of the circle and the issue date in the bottom half. Both capital and date on the front side of the vellum. The first internal issue shall be numbered. A. At the next internal issue the A and date are removed and a B together with the new issue date shall be written in the reserved places.

To keep properly track of these internal issues, the Project Engineer shall keep a record of the internal issues. This record is a very important document and can be a key document with regard to, e.g. material takeoffs.

3.3.4 The revisions shall be indicated by a “cloud” around the change and with the corresponding issue number within that cloud. The clouds shall be drawn with an orange colored pencil, e.g. color code 415, and on the BACK of the vellum. The clouds of previous issues shall be erased before new revision clouds are drawn on the vellum.

Note:

For changes/revisions on prints a standard BBV practice is to use the following color codes:

a. Equipment, lines, instruments, etc. removed from the drawing indicated with “red”, color code 426

b. Equipment lines, etc to be incorporated on the drawing indicated with “blue”, color code 443

c. Equipment lines, etc which are correct may be checked off with “yellow”, color code 407.

d. Remarks and additional notes which are not to be drawn on the vellum, “green”, color code 463.

Above color codes refer to the code numbers used by pencil manufacturer Faber-Castell, Gold Faber pencils. Other manufacturers have not necessarily the same code number system.

Instead of a red color for removing equipment, lines, etc a flesh-colored pencil may be used, which permits to draw new equipment and lines over the removed equipment. Use for this purpose pencil Faber-Castell Polychromos, code number 131.

Engineers are instructed to follow above system very consistently.

3.3.5 All changes on the diagrams shall be recorded on a “project Master” print of the last issue and kept at hand by the project engineer. All changes and/or additions made by others shall be passed through the project engineering department. It is the project engineer's responsibility to see that the diagrams are reissued every one, or at the most, every 2 months to keep all disciplines informed about latest revisions and changes.

3.3.6 All superseded “Project Masters” should be kept in the project file to provide a record of events.

3.4 Coordination

3.4.1 Copies of all correspondence, all specifications, all equipment vendor drawings and other pertinent job documents should be sent to the project engineer so that he may keep abreast of any and all changes which would affect the diagram. The project engineer shall forward all the relevant information to the different disciplines.

3.4.2 Any department, when making revisions or additions, which will affect a diagram, is required to notify the project engineer immediately, preferably in writing or to send hem his “master”. The project engineer will pass this information to the process engineer involved and update his master diagram accordingly for inclusion in the next diagram issue.

3.4.3 Revisions to precess flow diagrams must be brought to the attention of the project engineer. In this manner the project engineer will keep abreast of all process changes and will be able immediately to incorporate the changes into the engineering flow diagrams. After this updating by project, the process engineer will sent his “Master Copy” directly to the flow diagram squad.

It is necessarily for the process engineer to discuss contemplated changes with the project manger/engineer before changing the process flow diagram. The effect on fabrication and deliveries of equipment and/or materials, the client's or licensor's desires and construction schedule should be carefully considered and increasingly so as the job progresses.

4. The Process Flow Diagram (PFD)

4.1 General

After a project has been awarded the Process Department shall provide all special information required to commence engineering.

Process shall prepare a hand-sketched draft Process Flow Diagram which can be used for informing the various disciplines about the work to be performed. This normally is done at a formal kickoff meeting.

4.2 Initial Process Flow Diagram

The Process Department will prepare a had-sketched initial process flow diagram on preparinted standard vellums provided especially for this purpose (Form number E-B-UD15) (see example fig:5.)

The use of this sketch is two-fold. The sketch shall be used as a visual aid during the kickoff meeting and is the basis for the flow diagram squad to start drawing the process flow diagram proper. See example fig:6

4.3 Kick-off Meeting

4.3.1 Before engineering is started, a conference shall be called by the project manager to discuss the process and mechanical aspects of the job. This meeting should be attended by the job process engineer(s), project engineer(s), manager design engineering operations, design engineering supervisor, lead control systems engineer, lead piping engineer and other lead specialist engineers, as required.

4.3.2 A detailed explanation of the process shall be given by the process engineer. He outlines special considerations required for the location of related equipment, both in plan and elevation and calls attention to pipelines which must be arranged for gravity flow, tow-phase flow, self draining, etc.

At this meeting, the general philosophy of the control systems shall be discussed, particularly what types of instruments are to be local or remote, which indicators will be trend-recorded, the number of special analytic instruments, data loggers or other unusual requirements.

The process engineer should emphasize anticipated corrosion or erosion problems, explain the basis for the selection of materials of construction and review any special problems which must be considered in the mechanical design of the plant.

It is essential that the project engineer be given a thorough understanding of all process and operating problems at the project outset. In this way the information given on the initial diagram Layout will be as complete and accurate as possible.

4.4. Process Flow Diagram Drafting

4.4.1 Before the job starts, the project manager, in consultation with client or licensor, has to decide which system has to be followed, i.e. all process data, material balance, etc. should be shown on the process flow diagram proper, or that a separate set of material balance sheet will be prepared.

This information is necessary for the equipment layout on the diagram.

4.4.1 The flow diagram squad starts with the hand-sketched process flow diagram, from which the process engineer has given the explanations described in para 4.3.1, to make the process flow diagram on the proper format and with the standard symbols given in BN-ES-CI-1 and BN-ES-KI-1, or, if necessary, translate the Company symbols into symbols required by the client. This flow diagram will only be issued to the process engineer in charge to give on a print more information, such as heat duties, capacities, pressures, temperatures, equipment sizes on towers and drums, and capacities and P's for pumps.

4.4.3 It is essential to show a process flow diagram as simple as possible as far as mechanical details are concerned. It has to be avoided to show too many valves, etc. , and only the main instruments have to be given when laying out a process flow diagram. Ample space shall be provided for process data such as capacities, pressures and temperatures and instrument data on IDF sheet (see 1.5.6).

4.4.4 When all this information is shown on the process flow diagram, this will be officially issued by the project manager.

4.5 Reissues of Process Flow Diagrams

During the progress of the project the process flow diagram shall be reissued when necessary with the purpose of keeping all disciplines properly informed about the changes and corrections forthcoming during the engineering stage. For issue frequency and numbering see para 3.3 Issues are distributed in accordance with the job distribution schedule by the Project Department.

4.6 Computer Vision Diagram System

At the time this guide was updated and reissued plans to incorporate the means of producing flow diagrams by a computerized system were approved. In due time the guide will be updated to include the necessary information for generating computerized process flow diagrams and pressure-temperature profile diagrams. For example of such diagram see fig: 7

5. The Pressure-Temperature Profile Diagram (PTP)

5.1 General

The PT profile prepared by the Process Department is basically the process flow diagram on which for all critical flows through control valves and lines the following data may be given as deemed necessary for the project.

- Normal operating pressure

- Maximum operating pressure

- Normal operating temperature

- Maximum operating temperature

- Molecular weight

- Design pressure

- Design temperature

- Density

- Viscosity

- Normal flow

- Maximum flow

- Maximum temperature thermal stress

- Maximum shutoff pressure for pumps

- Set pressure of relief valves/break plates

- Differential pressure of pumps.

5.2 Purpose

The PT profile shall be used by all disciplines in order that the use the proper values of pressures and temperatures applicable to their specific requirements, e.g. pipe stress engineers, control system engineers, etc.

5.3 Reissues of PT Profile

The process engineer shall keep the data on the PT profile up to data and have the diagram reissued when necessary by the project manager.

The data on the PT profile must be “Certified Final” as early as possible, in order to minimize extra work because of process data changes.

5.5 Computer Vision Diagram Systems

When the computer vision diagram becomes operational (refer to para 4.6) the PT profile shall be made using the available info to produce a process flow diagram and the required PT profile data (see example fig: 7)

6. The Engineering Flow Diagrams (EFD)

6.1 General

A simplified block diagram showing the key elements of a systematic approach to flow diagram preparation is given in figure 8.

6.2. Initial Engineering Flow Diagram

6.2.1 The project engineer shall make the initial diagram layout for the engineering flow diagrams based on the process flow diagram. He should make the layout free hand and to full scale on the standard flow diagram vellum E-B-UD15 (see fig 5). The free hand edition should be initialed and dated by the project engineer and black and white prints distributed to the process and control systems engineers. See attached example, figure 9.

6.2.2 EFD General Layout

The EFD's shall be laid out with three horizontal zones across the sheet. Across the lower middle portion of the drawing is the “pipe alley” containing lines which enter and leave the sheet to other EFD's in the same unit plus lines running between pumps and other pieces of equipement on the drawing. Pumps and pump stations shall be located along a line below the “pipe alley”. All pump valving shall be lined up. All other equipment shall be located above a base line above the “pipe alley”. The general flow scheme shall be read from left to right. Unnecessary line crossing should be avoided. All line numbers and flow arrow shall line up as far as practical.

General notes for each unit are to be indicated on only the first sheet of the unit. The area above the title block on this sheet shall be completely left open for notes. Diagrams showing special equipment such as burner and compressor controls, etc shall have the related special notes on the same diagram.

6.2.3 Equipment

To be shown on the EFD:

a) Each piece of equipment including spares on the EFD of that particular unit. When an item is to be physically located inside the area of another unit it shall be so noted, exception may be made for situations where a large number of identical trains exist.

b) Pump item numbers and titles below the pumps “base line”. Indicate pump train designation only under each pump base (e.g. A.B.C.). When spares are required, the last pump of a train shall always be considered spare.

c) The other equipment item numbers and titles across the top of the flow scheme with the item number duplicated on or near the piece of equipment at its location on the diagram.

d) The equipment outline as simply as practical, but including all essentials and outlines, e.g. body flanges, domes, etc.

e) All connections and instruments on equipment. All connections whose purpose is not readily evident shall have the purpose indicated (examples: spare inlet, UC etc.), and the piping class to be used for the trim of the equipment.

f) Essential internals shall be shown in phantom so as to clarify the laction of connections relative to the internals. Vortex breakers are also to be indicated.

h) Motors on pumps only when connected to an interlock.

h) The support for columns and vessels supported by legs or a skirt.

j) A gap in the vessel support where a bottom outlet line crosses a vessel support.

k) Exchangers in side profile, with indication of expansion joints, tube side distribution baffles, etc., if any. Each shell te be shown and in relative position if stacked.

l) Bundles and fans on airfin coolers shall be shown simplified, but details on louvres, winterizing, running lights, temperature regulations and piping connections are to be shown if necessary on separate sketches.

m) A list next to the left hand side of the title block indicating the item numbers of equipment contained on the particular flow diagram.

n) Vendor-supplied packages only as a dashed/dot “box” with an outline of the main component(s) inside. At a proper time the reference drawing numbers are to be added.

o) The relative size of equipment – although no to scale.

p) The relative elevation of equipment – although not to scale.

q) Critical elevation notes as required.

r) Nozzle size when line size is different, reducers where applicable.

s) Existing equipment, when required, shall be shown with a dash-dot line, and marked “EXISTING”.

t) Manholes on columns/vessels.

u) Flushing/seal oil systems.

v) Start-up/shutdown lines.

6.3 Pipelines and pipeline referencing

6.3.1 All pipeline branching should be shown in proper sequence.

6.3.2 When lines cross one another, preference should be given to horizontal line, i.e. all horizontal lines should be continuous and vertical lines broken to cross them.

6.3.3 The procedure for cross referencing of pipelines going from sheet to sheet is as follows:

a) All main and process lines should enter and leave the diagram right or left (see figure 10) . An exception has to be made for lines coming or going to another unit. Those lines are coming in or leaving the sheet in a block (2x5cm) below the lowest pump base line (see figure 11).

b) Lines should enter and leave a diagram in a manner consistent with the actual process, where possible.

c) Whenever possible a line should match its continuation on a following diagram where possible. Line crossings as shown in fig 10 shall be kept to a minimum.

d) On each side of the flow diagram a dashed line shall be drawn to show from which diagram a line comes or to which one it goes. References and line numbers should also be added to lines where they enter or leave the sheet (see fig. 10).

e) A line shall not run across a sheet unless it ties into another line or piece of equipment on that sheet. It is permitted to skip one or more intervening sheets when running a line from one sheer to another.

f) All utility lines should be shown on the engineering flow diagram terminating in a diamond which shows the abbreviation as indicated on the legend sheet (see fig.12). The utility lines shown on EFD's shall only show instrument, valves, etc. directly related to the connected equipment (see fit. 13). The utility header valves and instruments will be shown on the utility flow diagram (see fig. 16). Example of legend, see fig:22.