Input variables

Generic variables

These variables can be found in virtually all reports as input variables

- Location – Location

- The physical location of the component

- Test medium – Test medium

- The medium used to test the component

- Design Pressure – P

- Pressure assumed to be present in the component according to the design terms.

- Design Temperature – Td

- Temperature assumed to be present in the component according to the design terms.

- Material (header/branch)

- Name of selected material used for the construction of the component.

Specific variables

These variables are component specific.

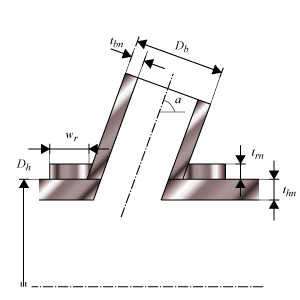

- Outside Diameter header and branch – Dh, Db

- Outside diameter of the attached part. The diameter runs from the outside of the wall to the opposite outside of the wall, through the center of the circle. Generally the branch is smaller in diameter than the header.

- Nominal Thickness header, branch and reinforcement – thn, tbn, trn

- Thickness ‘as is’, meaning it is the design thickness taking into account corrosion and tolerance.

- Corrosion header and branch – Ah, Ab

- Amount of thickness that accounts for the possible effects of corrosions.

- Tolerance header, branch and reinforcement – tolh, tolb, tolr

- Tolerance in thickness for production.

- Joint Efficiency header and branch – Eh, Eb

- Effectiveness of the strength, depending on whether joints are seamless, welded, or expected to perform worse than the base material properties.

- Angle centerline branch – a

- Angle between the centerline of the branch and the line perpendicular to the header centerline.

- Reinforcement width – wr

- Width of the reinforcement. The width equals the outer radius minus the inner radius.

Stubon dimensions

Stubon areas

Calculated Values

- Minimum yield strength at 20 °C header, branch and reinforcement – Syminh, Syminb, Syminr

- Stress in the component at which the component starts to plastically deform at 20 °C ambient temperature.

- Design factor – F

- Factor for the allowable stress when considering underthickness tolerance and maximum allowable depth of imperfections.

- Test design factor – Ft

- Factor for the allowable stress when considering underthickness tolerance and maximum allowable depth of imperfections.

- Allowable Operating Stress header, branch and reinforcement – Sh, Sb, Sr

- Stress in the component at which it is still allowed (without failure) to use the component.

- Allowable stress at 20 °C header, branch and reinforcement – Sht, Sbt, Srt

- Stress in the component at which it is still allowed (without failure) to use the component at testing condition.

- Header reinforcement zone length – d

- Length from the branch centerline to the end of the header reinforcement zone.

- Branch reinforcement zone length – L

- Length from the header outside diameter to the end of the branch reinforcement zone.

- Stress ratio branch/header – Sb/Sh, Sbt/Sht.

- Ratio of operating stresses of the branch and the header. This ratio must be ≤ 1.

- Stress ratio reinforcement/header – Sr/Sh, Srt/Sht

- Ratio of operating stresses of the reinforcement and the header. This ratio must be ≤ 1.

- Required thickness header pipe and branch pipe – thr, tbr

- Based on the input, this is the calculated thickness that is required to sustain the loads. The nominal value should be smaller than the nominal design thickness.

- Required reinforcement Area – AR

- The required cross-sectional area that reinforcement or excess thickness should provide for the opening.

- Reinforcement area header – A1

- Cross-sectional area of excess thickness header.

- Reinforcement area branch – A2

- Cross-sectional area of excess thickness branch.

- Reinforcement area of extra added area including weld areas – A3

- Extra reinforcement cross-sectional excess area.

- Total available reinforcement area – A

- The total available cross-sectional area from reinforcement and excess thickness. Sum of areas is corrected for stress ratios.

- Maximum Allowable Working Pressure – MAWP

- The maximum pressure at which the component can be used in operation.This value should be larger than the design pressure.

- Design margin – P/MAWP

- Ratio of the design pressure to MAWP

- Test pressure factor – FPt

- Factor for maximum test pressure based on design pressure.

- Maximum Allowable Test Pressure – MATP

- The maximum pressure at which the component should be tested and survive.

- Required Test Pressure – Pt

- Required hydrostatic pressure for testing at any point in the piping system (paragraph 437.4.1)

- Tapering header and branch

- The tapering of the header and branch on connecting pipes is checked.

Scope errors

- Temperature is out of scope: minimum temperature = -30 °C

- This code determines a minimum temperature.

- Temperature is out of scope: maximum temperature = 120 °C

- This code determines a maximum temperature.

- Angle branch is out of scope: required is 0° < α ≤ 90°.

- This code determines a minimum and maximum branch angle.

Errors

- Can’t find material ‘MaterialName’ in database

- Material could not be found in database. Select an existing material name, or select another material via the material selection window.

- Insufficient wall thickness for header

- Wall thickness is insufficient to bear the applied loads. Increase the wall thickness.

- Insufficient wall thickness for branch

- Wall thickness is insufficient to bear the applied loads. Increase the wall thickness.

- Insufficient reinforcement area

- Reinforcement area is too small. Increase the reinforcement width or wall thickness of reinforcement, header or branch.

Warnings

- Tapering header in reinforced zone.

- Indicates tapering of header in reinforced zone.

- Tapering branch in reinforced zone.

- Indicates tapering of branch in reinforced zone.